Simvastatin is a synthetic statin medication that lowers LDL cholesterol by inhibiting HMG‑CoA reductase. The drug saves millions of lives, but its manufacturing can strain ecosystems. This article walks through the production steps, pinpoints the biggest environmental impact sources, and shows how the industry can shift toward greener practices.

Every year, global demand for Simvastatin exceeds 2billion tablets. That volume translates into a massive supply chain of raw chemicals, energy, and waste streams. Understanding the scale helps stakeholders see why even modest improvements can cut tons of emissions.

Statins are a class of drugs that reduce blood cholesterol via the HMG‑CoA reductase pathway. While Simvastatin is one of the most widely prescribed, it shares a common manufacturing backbone with other statins. The chain includes:

Each node adds energy use, emissions, and waste, creating a cumulative footprint.

Key environmental hot spots appear in steps 2‑4, where large volumes of organic solvents and energy‑intensive heating are used.

Recent LCA studies (e.g., European Medicines Agency 2023 report) reveal four main contributors:

Understanding these numbers helps companies set realistic reduction targets.

Carbon accounting typically follows the GHG Protocol scopes:

The pharmaceutical industry’s average Scope3 emissions can dominate the total, especially for imported solvents. For Simvastatin, Scope3 often accounts for more than 60% of the total carbon footprint.

Green Chemistry a design philosophy that minimizes hazardous substances and energy use in chemical processes offers concrete pathways to cut Simvastatin’s impact. Below are three proven techniques:

Adopting any of these methods can also lower production costs over time, as waste disposal fees decline.

| Attribute | Traditional | Green Approach |

|---|---|---|

| Energy Use (kWh/kg API) | 1,200 | ≈650 (continuous flow) |

| Solvent Toxicity | High (methanol, toluene) | Low (water, supercritical CO₂) |

| CO₂ Emissions (t/ton API) | 5.0 | 3.2 (renewable electricity) |

| Waste Generation (kg/ton API) | 200 | ≈80 (higher selectivity) |

| Water Usage (m³/ton API) | 1,500 | 1,000 (recycling loops) |

The table highlights that a shift to greener chemistry can slash energy demand by ~45% and waste by more than half.

Wastewater Treatment processes that remove contaminants from industrial effluents before discharge is another lever. Modern plants use membrane bioreactors combined with advanced oxidation (e.g., UV/H₂O₂). This not only meets EPA limits but also recovers solvents for reuse, reducing raw‑material demand.

Regulators worldwide push for greener pharma. The U.S. EPA’s Clean Water Act imposes strict limits on VOCs, while the EU’s EMA guidelines encourage LCA reporting for new drugs. The WHO’s “Pharmaceuticals in the Environment” technical series (2022) recommends a 30% reduction target for carbon intensity by 2030.

Companies can follow a phased roadmap:

These actions not only improve environmental performance but also boost brand reputation and can lower operating costs.

Consumer awareness is rising; patients now ask about the carbon footprint of their prescriptions. Investors are also scrutinizing ESG metrics. Companies that embed green chemistry into Simvastatin production will likely enjoy market share growth, regulatory goodwill, and lower risk of fines.

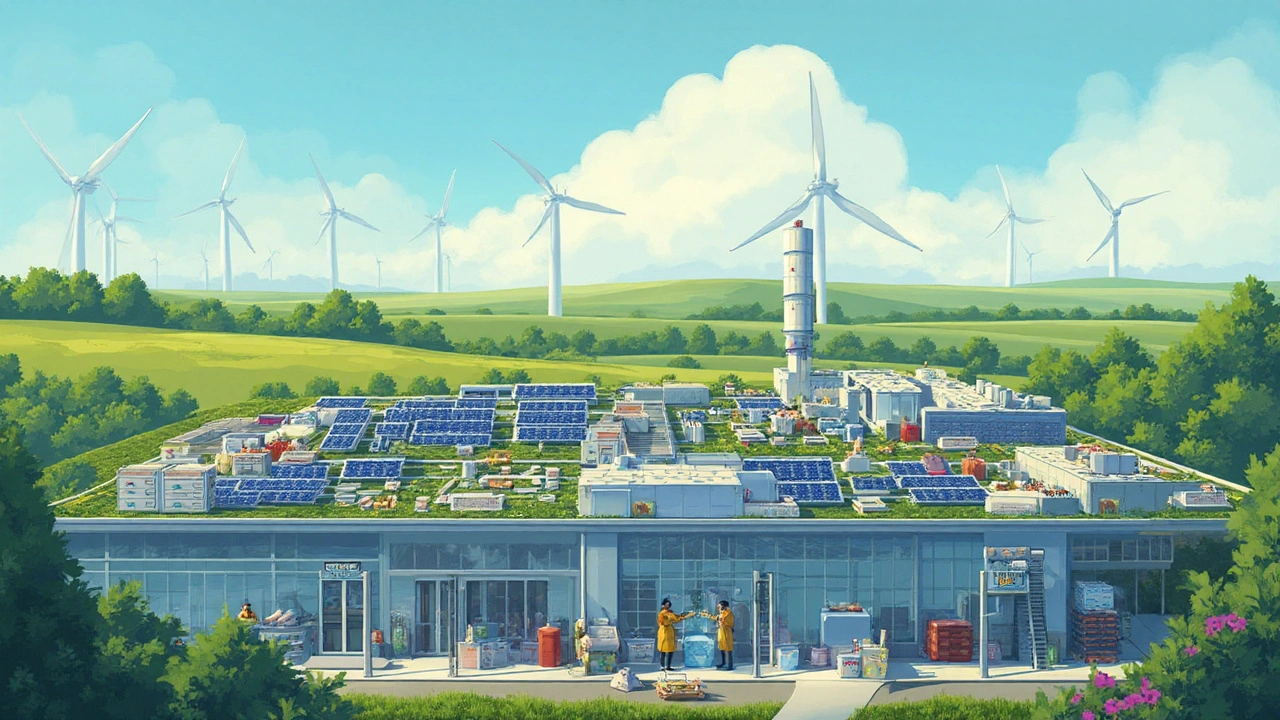

Understanding Simvastatin’s environmental profile touches on several broader topics, including pharmaceutical waste management, industrial ecology, renewable energy integration, and closed‑loop manufacturing. Exploring these adjacent areas can deepen insights into how the entire health sector can move toward sustainability.

The biggest contributors are furnace‑driven heating for reactions, electricity for solvent recovery, and the transportation of raw chemicals. Together they make up roughly 70% of the product’s carbon footprint.

Yes. Although initial investment for new equipment (e.g., flow reactors) can be high, the reduction in solvent purchases, waste disposal fees, and energy consumption often leads to a net cost saving within 3‑5 years.

Modern treatment removes residual solvents and recovers them for reuse, cutting both raw‑material demand and toxic discharge. Membrane bioreactors also lower energy use compared to conventional activated sludge systems.

Many jurisdictions offer tax credits or expedited review for facilities that meet strict emission thresholds or demonstrate ESG compliance. The EU’s EMA also provides a “green label” for pharmaceuticals with verified low‑impact LCA results.

Enzymes catalyze esterification steps at ambient temperatures, eliminating the need for high‑heat reactors and reducing by‑product formation. This leads to higher yields and less solvent waste.

Write a comment